Asphalt Plant Process Flow:

- Atlas Technologies

- Dec 28, 2020

- 3 min read

The process flow of any asphalt plant will depend on the type of plant. Right now we have different types of asphalt mixers available in the market. These mixers are build keeping in mind different customer types.

There are two major types Of categories batch type and continuous type:

Batch type: With this design, the production of the hot mix will be done in batches of specific sizes.

Continuous type: Here the production of HMA will be done in a continuous process.

As the process of each type changes, the quality of the end product also differs.

Continuous asphalt plant process flow:

The starting point of the asphalt drum mix plant process is the continuous feeding of cold aggregates into the feeder bins. Aggregates have to be fed as per the size into different feeder bins. The number of bins is three, four, or even more. The flow of aggregates from individual bins are controlled as required by the mixed material design. This flow is also controlled and regulated by the control panel.

Related: Click here to see complete details, photos, catalog of asphalt batch plant

The primary vibrating screen will screen the oversized material and aggregates will enter the drum for heating and then mixing. The drum mixer will evenly apply heat to the aggregates and then coat them uniformly with bitumen as aggregates pass from one end of the drum. The drum unit is inclined and rotating that facilitates easy flow of aggregates from one end to the other. Fuel for the bitumen tank drum burner is stored in a separate tank.

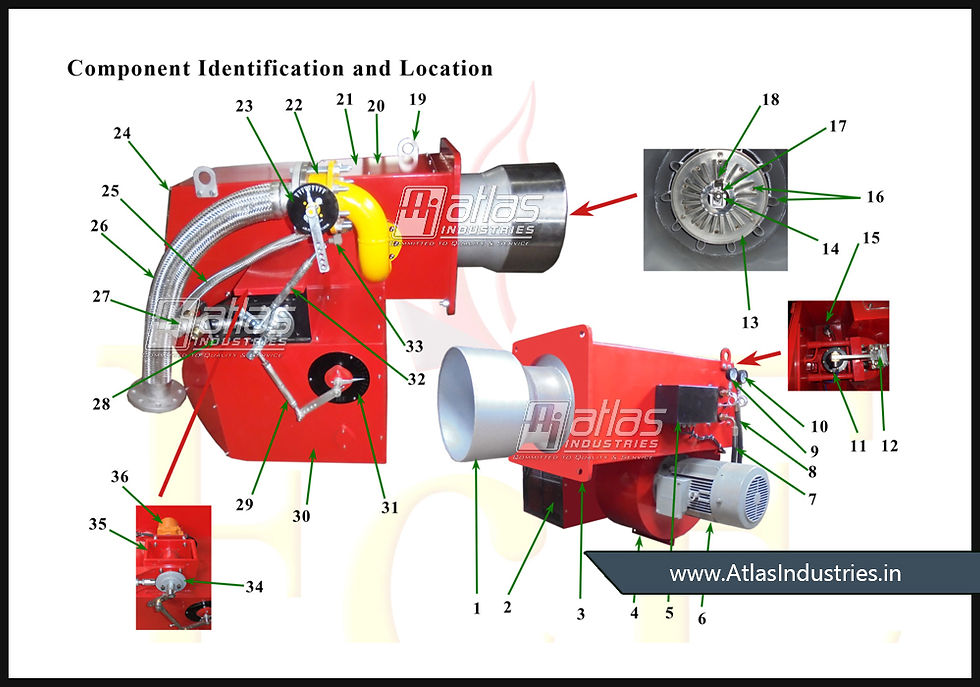

See the image below to understand asphalt drum mixing plant operations.

Bitumen and filler material are the ones that are added into the drum for mixing with aggregates. Bitumen is stored in separate tanks and then added into the drum by a pipe line by a bitumen pump controlled by a variable speed drive motor. Filler material is stored in separate filler hopper and transferred by means of a compressor.

Pollution control is taken care of by dry and wet type pollution control devices. After proper mixing, the hot mix is discharged to the other end of the drum and onto a conveyor. This conveyor takes the HMA into the waiting trucks or storage silos.

All these processes are controlled by a computerized control panel that comes with the asphalt mix plant.

Batch asphalt plant process flow:

The process or flow for the asphalt plant – batch type starts the same way as we have to feed the aggregates into separate feeder bins. The aggregates then pass through a primary vibrating screen that helps in the removal of oversized material. After that, the aggregates are treated to heat in a drum which is fitted with a burner unit.

Dust suction is done at the entry point of the aggregates into the drum and the dust absorbed is treated by a pre-separator and then by a bag filter unit.

The heated aggregates are then transferred to the top of the mixing tower into the vibrating screen. Vibrating screen has screens of different sizes laid out for the separation of aggregates. After separation, aggregates are stored in different bins as per their size.

This area is called hot bins and it is just below the vibrating screens.

See the image below to understand the asphalt batching plant operation:

On the other hand, bitumen which is stored in the storage tanks is transferred to the weigh hopper near the mixing unit. The same happens for filler material as it gets transferred to its weigh hopper.

Aggregates will be weighed and then discharged into the mixing unit by opening of pneumatic cylinders as set in the control panel. Bitumen and filler material are also added by weight into the mixing unit to complete the batch. Batch mixing time is set in the control panel and after the mixing time is over, the pneumatic gates below the mixing unit will open leading to the discharge of hot mix asphalt into the storage silo or directly into waiting trucks.

Now-a-days these asphalt mixing plants come with advanced control panel that show display of all important parameters and also allow adding, removing and editing of recipes. All important mix material data can be viewed and printed from the control panel or stored into pen drive.

More information About Visit My Website>>https://www.atlastechnologiesindia.com/

For the best hydrated lime manufacturers in Jodhpur, trust Rajasthan Lime & Minerals Pvt. Ltd., committed to delivering high-quality lime solutions for various applications."